Drying of food

Practical Action

The collectors are covered with a transparent material to ensure uniform airflow. Glass covers

are best but they break easily, are heavy and expensive. Plastic often has poor stability to

sunlight and weather, but is about 10% of the weight of glass and does not break. The best

types of plastic are polyester and polycarbonate when available. Polythene is cheaper and more

widely available but is not as strong and is less resistant to damage by light and weather.

The drying food can either be exposed to the sunlight (in direct systems) or dried indirectly by

passing heated air over the food. In the indirect system the drying food is shaded, which helps

to retain the colour and nutrients that are light-sensitive. Direct systems are used for food such

as raisins, grains and coffee where the colour change caused by the sun is acceptable. However,

most foods need indirect systems to protect the colours in the food. Other types of dryers use

fans to blow the air over the food but this adds to the capital and operating cost and removes the

advantages of dryers in rural areas which can not operate without electricity.

There are three basic types of solar dryer, each of which has many variations;

1. tent dryers (direct)

2. cabinet dryers (direct or indirect)

3. chimney dryers (indirect).

Each of these types of dryer uses natural air circulation although it is possible to fit an electric or

wind powered fan to increase the flow of air through the dryer.

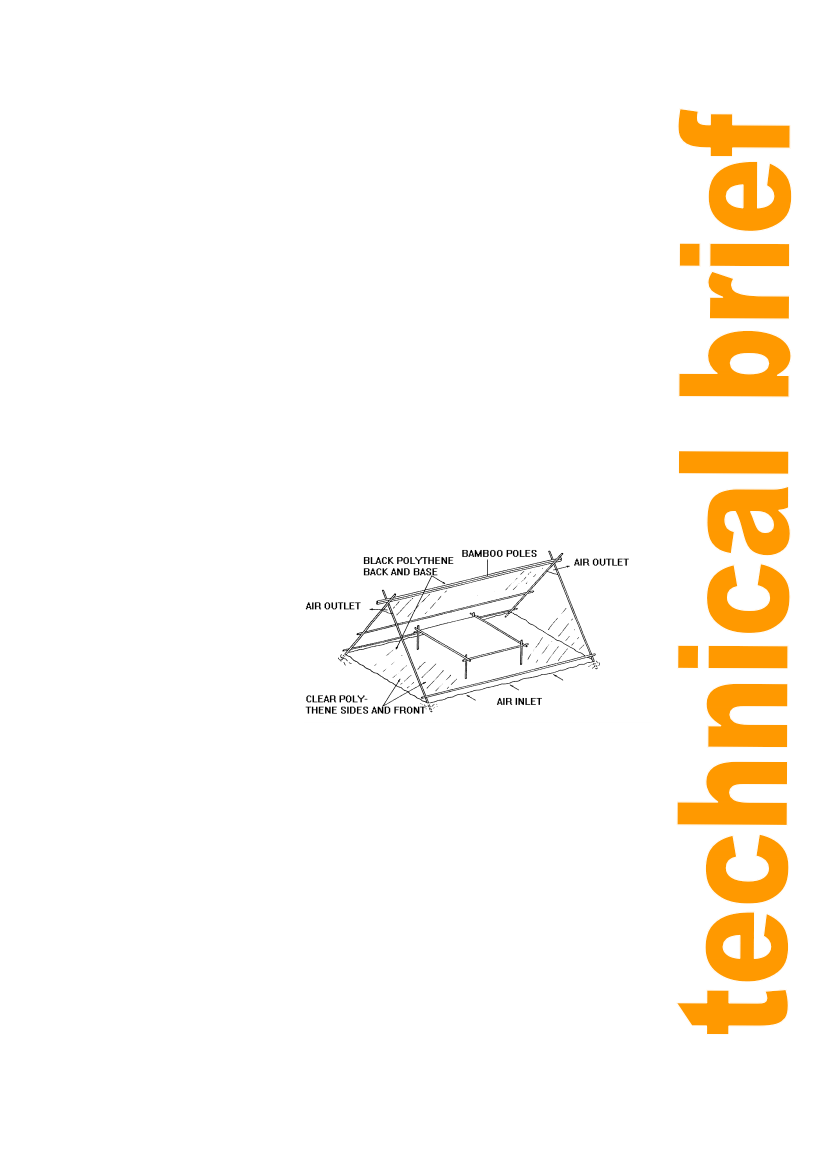

Tent dryers

This type of solar dryer consists of a

ridge tent framework, covered in

clear plastic on the ends and the

side facing the sun, and black

plastic on the base and the side in

the shade. A drying rack is placed

along the full length of the tent.

The bottom edge of the clear plastic

is rolled around a pole, which can be

raised or lowered to control the flow

of air into the dryer. Moist air leaves

through holes in the top corners of

the tent.

The advantages of this type of dryer

are the low construction costs and

simplicity of operation. However,

like other types of solar dryer, there

is relatively poor control over the RH

of the air in the dryer and so, poor

control over drying rates. It is also

lightweight and fairly fragile when

moved or in windy conditions.

Figure 6: Tent solar dryer

Cabinet dryers

The basic design is an insulated rectangular box, covered with clear glass or plastic. There are

holes in the base and upper parts of the box to allow fresh air to enter and moist air to leave.

The inside of the cabinet is painted black to act as a solar collector. In indirect types, a flat

plate is painted black and suspended in an insulated frame. Air is heated on both sides of the

plate before passing into the drying cabinet. Food is placed on perforated trays within the

cabinet and warm air from the collector rises up through the food and leaves through the top.

The length of the cabinet is approximately three times the width to prevent shading by the

sidewalls.

9